Technical data

You are here: / Start / Products / transformer houses and buildings / SCHEIDT INDIVIDUAL SH / Technical data

SCHEIDT INDIVIDUAL SH

SCHEIDT INDIVIDUAL SH in detail.

Your boat, your car, your transformer house. We build the last of these for you – because we know exactly how to make it perfect. Tell us what it should look like!

Further information

Key benefits:

Prefabricated C35/45 reinforced concrete buildings

Produced in element construction, can be produced in almost all dimensions

Single and multi-floor

With different roof types

Short construction time due to prefabrication/installation of the individual elements in the factory

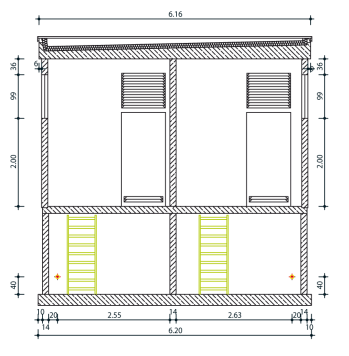

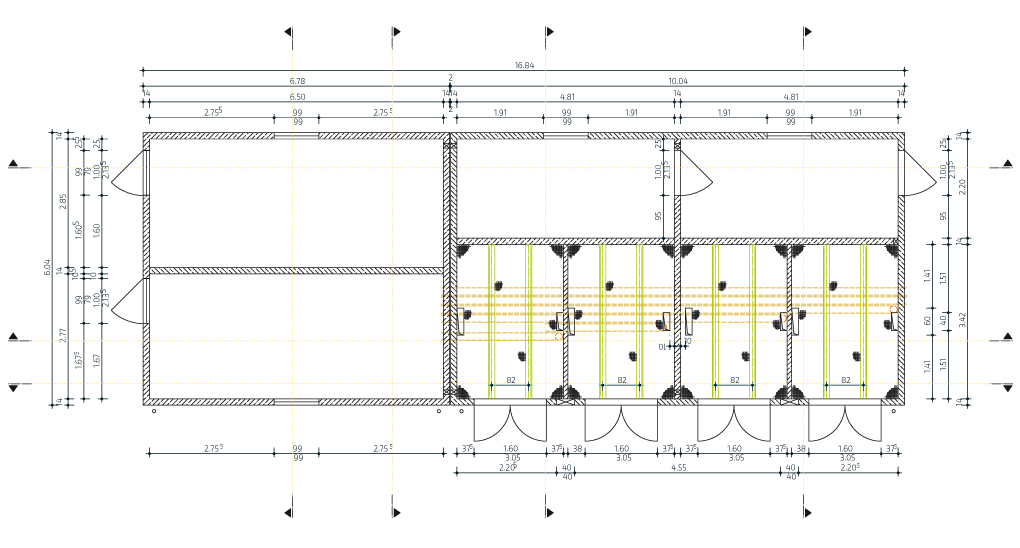

Basement:

Made in the factory

Monolithic without working joint

Highest possible water and oil resistance without additional coatings

Width at least 3 m to max. 5 m

Length at least 6 m to max. 12 m

Additional dimensions: Composition by individual components or a WU in-situ concrete basin

Oil collecting surface can optionally be coated with oil-resistant paint

Sealing of the basin with WHG-approved system possible

Sealing systems for cable and/or pipe penetration of various certified manufacturers in use

Intermediate floor

To accommodate switchgear and building technology

Concrete intermediate floor/concrete floor panel constructed using prefabricated concrete elements or cast in in-situ concrete (thickness according to static requirements)

Optionally elevated intermediate floor made of non-slip coated composite wood panels

Installation of transformers on adjustable, galvanized steel transformer rails possible

Walls

Tightly connected roof and wall elements

Prefabricated walls rest on strip foundations, basement walls or concrete intermediate floors

Roof

Standard cassette roof with 2% roof slope

All-round concrete fascia composed of one or more separately manufactured elements

Moisture protection

Individual roof elements are rigidly connected to each other and the walls

Common variants: e.g. flat and saddle roofs

Other special roof shapes (e.g. saddle roof/wooden constructions) available according to the customer’s wishes

Facades:

Station body outside with highly elastic structure coating

At customer request, facade design of the building with e.g.:

- Friction-effect plaster

- Pebble plaster

- clinker

- Exposed aggregate concrete

- Design as a framework imitation

- graffiti, …

Interior features:

Interior walls, including the inside of the roof, are coated with a white, wash-resistant binder paint

Integration of anchor rails or threaded bushes possible

Empty pipes can be embedded in concrete for the electrical installation

Rails, bushes and reinforcement, as well as all metal parts of the station body which are not part of the operating circuit, are conductively connected to each other, so that a common earth connection can be routed from the station

Doors and ventilation:

On the front and long sides, various built-in parts such as doors, ventilation grates, pressure relief flaps or windows of various sizes and different materials can be installed as required

Ventilation systems in the roof possible, such as roof ventilation hoods, pressure relief hoods and fans

The built-in doors with 3-point locking and panic lock are prepared for on-site profile cylinders

Building assembly/combination

Assembly/compilation of the building: on the construction site